Log data out-the-box. Standalone - no PC required. Power via CAN connector

Only 8 x 5 x 2 CM. 100G. Aluminium enclosure. 4 LEDs. Configurable 5V power out (CH2)

Filters. Transmit lists. Routing. Triggers. Cyclic logging. Silent mode. Encryption

Built-in GNSS/IMU. 3X accuracy via sensor fusion. Position, speed & more. Route to CAN

Pro specs CAN logger

- at half the cost

The CANedge1 combines innovative design, cutting-edge components - and incredibly low costs:

- 2 x CAN (incl. CAN FD) + 2 x LIN channels

- Extractable 8-32 GB industrial SD card (= months of data)

- Popular binary MDF4 log file format

- Advanced message filtering & transmit functionality

- Route data from CAN1/2, LIN1/2 and GPS/IMU onto CAN1/2

- Start/stop logging triggers based on CAN ID & databytes

- Silent mode, bit rate auto-detection, cyclic logging

- Data compression & encryption (e.g. for GDPR, CCPA)

- Support for CAN/LIN error frame logging

- Fast boot time. Safely disconnect during use (power safe)

- Add CANmod to e.g. log 5 x CAN or temperature/analog data

GPS & 3D IMU - enrich your data

The CANedge1 comes with cutting-edge GNSS/IMU functionality - perfect for automotive/maritime use cases.

- Add 40+ GNSS/IMU signals to your 2 x CAN/LIN data

- Full GNSS support (GPS, Galileo, BeiDou, GLONASS)

- Built-in gyroscope (roll, pitch, yaw) and accelerometer (X, Y, Z)

- High precision via sensor fusion - even in GNSS hostile areas

- Signals encoded as 'internal' CAN frames (separate channel)

- Configurable message inclusion/frequency (up to 5 Hz)

- DBC file included for easy decoding to human-readable form

- Optionally sync the CANedge RTC via precise GNSS time

- Flexible deployment via external GNSS antenna

Position + sensor fusion

Add time-synced GPS positioning to your CAN/LIN data - with sensor fusion (UDR) for 3x higher accuracy.

Speed

Speed data is useful in e.g. fleet telematics to identify speeding, idle time, asset utilization rates and more.

Altitude

Altitude is key in e.g. analysis of fuel/battery consumption - or e.g. in aerospace applications like drones, planes etc.

Attitude

The GNSS/IMU enables attitude data, giving a 3D view of the asset orientation at any time [automotives].

Trip distance

Odometer data enables easy tracking of the trip distance travelled by the asset (since last module power cycle).

Angular rates

3D IMU angular rates can be used in e.g. the analysis of driving and vehicle dynamics (tire/suspension, drifting, ...).

Acceleration rates

3D IMU acceleration rates can be used in e.g. analysis of driving quality and predictive maintenance.

Geofences

Configurable circular geofences are useful for e.g. theft prevention, safety, automation and more

Timestamp

The high precision epoch timestamp is useful e.g. in syncing the CANedge real-time clock.

Open source software/API

- naturally

The CANedge1 uses open formats (MDF4 data, JSON config, S3 server) - and all software/APIs are 100% free and open source.

The software toolbox includes:

- Editors: Easily modify your device config (online/offline)

- Converters: Convert data to Vector ASC, PEAK TRC, CSV, ...

- asammdf GUI: DBC decode, plot and export your data

- Python API: Automate your data processing & integrations

- Dashboards: Visualize data in custom browser dashboards

Check out our tech specs, use cases or FAQ - or buy now!

Do you have any questions?

Contact us| GENERAL | |

|---|---|

| Functionality | Standalone CAN bus data logger with SD card and 2xCAN/LIN channels (incl. CAN FD) and GNSS/IMU |

| Firmware | Supports free firmware updates for adding features |

| Configuration | Configuration files based on the popular open source JSON schema concept |

| Software | Free open source editor tool for easy device configuration (offline/online version available) |

| Free open source asammdf software & API for editing, DBC converting & plotting MDF4 data | |

| Free open source MF4 converters - drag & drop log files to convert into e.g. CSV, ASC, TRC | |

| Free open source Python API - e.g. for automated data processing, reporting or integrations | |

| Free open source telematics dashboards for visualizing your DBC decoded data in your browser | |

| Safety | CE-RED, FCC, IC, RoHS, ECE R10 (automotive EMC), KC (Korea), ICASA (South Africa) |

| Warranty | 1-year warranty |

| Support | Free, fast & high quality support |

| Origin | Denmark |

| CAN BUS | |

| Channels | 2 x CAN channels (incl. CAN FD support) |

| Standard | ISO 11898: Compliant with CAN (up to 1 Mbit/s) and ISO & Bosch CAN FD (up to 5 Mbit/s payload rate) |

| Protocols | Log raw data from CAN based protocols (J1939/FMS, CANopen, NMEA 2000, OBD2, CAN FD, UDS, ...) |

| Identifiers | Compliant with CAN specifications 2.0A (11-Bit ID) and 2.0B (29-Bit ID) |

| Bit-Rate Auto-Detect | Bit rate can be auto-detected or set manually |

| Retransmission | Configurable retransmission of frames that have lost arbitration or been disturbed by errors |

| Transceiver Protection | ±16 kV HBM ESD, ±15 kV IEC ESD, ±70 V bus fault, short circuit |

| Common mode input voltage: ±30 V | |

| TXD dominant timeout (prevents network blocking in the event of a failure) | |

| LIN BUS | |

| Channels | 2 x LIN channels |

| Publisher/Subscriber | Each LIN channel can be configured as a LIN subscriber/publisher with support for LIN data transmission |

| Custom length | Support for custom frame lengths |

| Standard | Compliant with LIN 2.0 up to 20 Kbit/s (support for Classic & Enhanced checksum format) |

| Transceiver Protection | ±8 kV HBM ESD, ±1.5 kV CDM, ±58 V bus fault |

| TXD dominant timeout (prevents network blocking in the event of a failure) | |

| DATA LOGGING | |

| SD Card | 8 GB extractable Class 10 industrial micro SD (SDHC) included (optional 32GB) - read at 80 MB/s

i

The device uses a class 10 industrial micro SD card with strong specs:

|

| Parallel CAN/LIN | Record data from up to 2 x CAN channels + 2 x LIN channels, simultaneously |

| Real-Time Clock | Yes - CAN frames are date & timestamped with 50 microsecond resolution (battery backup) |

| The RTC can be configured to match local time zones (default: UTC) | |

| The RTC can be auto-synced via a CAN message (e.g. from the internal GNSS timestamp) | |

| Log File Format | Log data in industry standard binary MF4 (easily convert to e.g. CSV, ASC, pandas, MATLAB, ...) |

| Data Compression | Configurable embedded log file zipping (~50-80% size reduction) |

| Silent Mode | Configurable silent mode: Restricted (acknowledge only) or monitoring (zero transmission) |

| Filters | 128/64 regular/extended ID filters per channel (range, mask, acceptance, rejection, prescaling) |

| Prescaling | Prescale CAN frames to record e.g. by time (per X ms) or by data (e.g. if byte X or Y changes) |

| Transmit | Transmit lists of CAN frames per channel (single-shot/periodic) - e.g. for OBD2/UDS/XCP/J1939 requests |

| Gateway Routing | Data from CAN1/2, LIN1/2 and CAN9 (GPS/IMU) can be routed onto CAN1/2 (with optional ID re-mapping) |

| CAN Error Frames | Support for logging CAN error frames (bit-stuffing, form, CRC, bit, acknowledgement) |

| LIN Error Frames | Support for logging LIN error frames (checksum, receive, synchronization, transmission) |

| Remote Frames (RTR) | Support for logging/transmission of remote CAN frames (RTR) |

| Cyclic Logging | Optional cyclic logging mode (oldest log file is deleted when SD card is full) |

| Advanced Triggers | Control signal lets you start/stop logging based on custom CAN IDs & data thresholds |

| CAN Heartbeat | Optionally transmit heartbeat CAN frame with device status, storage used & RTC time |

| File Split | Configurable log file split size (by size: 1-512 MB and/or by time period: 0-86400s) |

| Power Safe | 100% power safe data logging - no file corruption when disconnected |

| Unique Device ID | Each device has a globally unique ID ensuring unique log file naming |

| Data Encryption | Log files can be encrypted at rest on the SD card for security/GDPR/CCPA purposes |

| GNSS & 3D IMU | |

| Module | Professional-grade u-blox NEO-M9V sensor module (92-channel) with built-in gyroscope and accelerometer |

| GNSS | Supports combinations of GPS (USA), Galileo (Europe), BeiDou (China), GLONASS (Russia) |

| Sensor Fusion (UDR) | Enhanced position precision via sensor fusion (UDR) of GNSS and 3D IMU [automotives only] |

| Up to 3x better accuracy vs. GNSS-only receivers | |

| Extended and improved GNSS fix in GNSS hostile areas (e.g. urban environments, tunnels, ...) | |

| Accuracy | Position: 2.0 m CEP (Circular Error Probable) |

| Heading: 0.3 deg | Pitch: 0.4 deg | Roll: 0.6 deg (68% at 30 m/s) | |

| Velocity: 0.08 m/s | |

| Sensitivity | Tracking/Navigation: 160 dBm | Cold starts: 148 dBm |

| Acquisition | Cold starts: 25 s |

| GNSS Antenna | Required for GNSS-based data (not for IMU) |

| DATA PARAMETERS | |

| CAN encoding | The GNSS/IMU data is encoded as 'CAN messages' within the CANedge log files (on a separate channel) |

| Configuration | GNSS/IMU messages can be filtered/prescaled to enable custom message inclusion and frequency |

| Optionally record GNSS/IMU messages only if valid | |

| Signals | The module adds several GNSS/IMU signals (for a full list, see the Docs or DBC file) |

| GNSS position: Longitude and latitude information [5 Hz] | |

| GNSS time: Precise GNSS based epoch timestamp [5 Hz] | |

| GNSS status: Fix type (NO/UDR/2D/3D/GNSS+UDR) and satellite count [5 Hz] | |

| GNSS speed: Travel speed in m/s and km/h [5 Hz] | |

| GNSS altitude: Altitude in meters [5 Hz] | |

| Attitude/orientation: Roll, pitch, heading [automotives only] [5 Hz] | |

| GNSS odometer: Distance traveled (since power on) [5 Hz] | |

| 3D IMU: Accelerometer-based acceleration (X, Y, Z) [5 Hz] | |

| Geofences: Status of the configured geofences [5 Hz] | |

| ELECTRICAL | |

| Input Supply | +7V to +32V DC via the Channel 1 DB9 (e.g. via CAN connector power pin) |

| Power Consumption | Extremely low (~1 W) - no risk of battery drainage |

| Protection | Reverse voltage protection on CAN-bus supply |

| Transient voltage event protection on supply lines | |

| MECHANICAL | |

| Enclosure & Weight | Compact aluminium enclosure: 75 x 47 x 20 mm (W x L x H excl. flanges). 100 grams |

| Antennas | GPS antenna included |

| Flanges | Flanges with 4 x M3 screw holes (head diameter < 6 mm) - see also the CANedge 'mounting kit' |

| Connector | 2 x Standard D-sub 9 (DB9) connectors (optional OBD2/J1939/... adapters) |

| Pin-Out | See the product manual for the DB9 connector pin-outs |

| Configurable Power Out | Channel 2 can be configured to supply 5V to external modules (e.g. the CANmod sensor-to-CAN modules) |

| LEDs | Logger status via 4 external LEDs: Power, CH1, CH2, Memory |

| Temperature | Operating temperature (parts): -25degC to +70degC |

| IP Rating | IP Rating 40 (optional IP67 enclosure kit available) |

The CANedge1 is a powerful, standalone CAN logger for standalone CAN logging, diagnostics and development.

Note: If you need to remotely collect data via WiFi or 4G LTE check out the CANedge2 or CANedge3.

Vehicle blackbox / Event Data Recorder (EDR)

Need to monitor data from your vehicle fleet?

The CANedge1 is ideal for recording data over long periods from fleets - incl. cars (via OBD2) and heavy-duty vehicles (via J1939). With filters, compression, data encryption and cyclic logging you can safely log the latest months or years of data. This makes the device well-suited as an automotive data logger for e.g. warranty/legal data storage or optimization. Further, by adding GNSS/IMU data, you'll be able to exactly pin-point where an issue occurred - and time-sync it to valuable information about driving behavior and vehicle dynamics. This also makes the CANedge1 an excellent Event Data Recorder (EDR) for e.g. UN R160 or UN R169 requirements.

Rare issue identification

Need to identify a rare, but critical issue?

If you have e.g. production equipment that periodically exhibts an issue the CANedge1 is a great diagnostics tool. Simply connect it and leave it in, creating a rolling window of e.g. the last X months of data. If the issue occurs, you can extract the raw data, DBC decode it and plot it for quick diagnostics. Further, with the built-in IMU, you can deploy the CANedge1 so as to gain e.g. acceleration or angular rate data from e.g. industrial robotics or machinery to aid in your diagnostics.

Equipment development & optimization

Need to optimize your CAN based equipment based on long-term data?

The standalone CANedge1 is ideal for recording data from equipment deployed in the field: It is durable, compact and simple to install. You can e.g. pre-configure the device - and ship it to the end-users for installation. Further, the GNSS/IMU module adds 40+ signals like position, speed, acceleration, distance and more - enhancing your insights. Further, the built-in sensor fusion ensures that these signals gain three times the accuracy vs. GNSS-only receivers.

Yes, this version of the CANedge includes a GNSS/IMU module. If you install the device with an external GNSS antenna, this lets you optionally record GNSS/IMU data in time sync with your 2 x CAN/LIN data.

The GNSS/IMU information is recorded as if the data was being broadcast on a CAN bus network recorded by the CANedge. To separate it from the CAN/LIN channels, the data is stored in the log files under a separate 'internal' pseudo channel.

Previously, adding GNSS/IMU to the CANedge required connecting a GPS-to-CAN module (like the CANmod.gps) to the CANedge (e.g. on the 2nd port).

The new internal GNSS/IMU achieves a number of advantages:

- It is far more compact - and easier to install

- Total cost is drastically reduced

- The 2nd CAN channel of the CANedge is 'freed up' for logging CAN data

- The internal GNSS messages are available at up to 5 Hz vs. 1 Hz

- The GNSS/IMU is now configured via the CANedge Configuration File

- The GNSS timestamp can be used to sync the CANedge RTC (eliminating drifting)

The CANmod.gps is, however, relevant if you need to add GNSS/IMU data to another CAN bus system. Further, the CANmod.gps supports a 100 Hz output rate for the IMU based messages (angular and acceleration rates) vs. 5 Hz for the internal GNSS/IMU.

The CANedge is the 2nd generation of the CLX000. We generally recommend to use the CANedge for data logging use cases, while the CLX000 is mainly recommended if you need to stream data via USB.

Key improvements in the CANedge vs. CLX000 include:

Mechanical

- Extractable SD: The SD can be extracted to transfer data at 80 MB/s (vs 0.5 MB/s for the CLX000 via USB)

- Industrial SD: The CANedge uses an industrial SD card, improving performance, life time, temperature range & more

- Channels: 2 x CAN/LIN channels, enabling logging of 2 x CAN + 2 x LIN in parallel

- Aluminum enclosure: New enclosure is as compact as the CLX000, but far more robust and offers flanges for mounting

- Power out: Power external modules via the 2nd port, e.g. a GPS-to-CAN or Temperature-to-CAN module

- Rugged protection: The CANedge comes with a stronger protection spec against e.g. voltage spikes

Log files & software/API

- MDF4 log files: Popular binary MDF4 format - more compact than CSV, faster to process, supported by many CAN tools

- Configuration: Open source configuration editor can be used either online/offline via your browser

- JSON Schema: Config files are based on the standardized JSON Schema concept, supported by many open source tools

- Converters: Open source light-weight converters enable drag & drop/CLI conversion of MDF4 into e.g. *.csv and *.asc

- asammdf GUI: Enables user-friendly MDF4 log file editing, DBC-conversion (incl. OBD2/J1939), graphical plots & more

- Python API: Easily process your data at scale and automate the creation of e.g. reports/databases/dashboards

- MATLAB: Log files integrate natively with MATLAB's Vehicle Network Toolbox

- Dashboards: Easily visualize your data in free customizable Grafana dashboards

Data logging

- Lossless: The CANedge can log full bus loads with zero message loss (the CLX000 is limited to ~800-1000 frames/sec )

- Compression: Optional compression lets you reduce file size by up to 80% vs. the CLX000

- Encryption: Optional encryption lets you encrypt log files on the SD card for added security

- Advanced configuration: More advanced filters & transmit lists (e.g. up to 128 filters vs. 8 on CLX000)

- Precision: 20x higher RTC resolution (50 micro seconds) - with advanced RTC sync options

- Boot time: Much faster boot time vs the CLX000 (~1 sec vs. ~10 sec)

- CAN FD: The CANedge supports CAN FD (Flexible Data-Rate), making it future proof

- Triggers: Control when to start/stop logging/transmission based on custom CAN signal thresholds

- Error frames: The CANedge supports CAN/LIN error frame logging

- LIN slave/master: The CANedge can both serve as a LIN slave or LIN master (publisher)

GNSS/IMU + connectivity

- GNSS/IMU: The CANedge supports optional built-in GNSS/IMU functionality

- WiFi: The CANedge2 supports WiFi data transfer to your own cloud/self-hosted server (incl. OTA updates)

- 4G LTE: The CANedge3 supports 4G LTE data transfer to your own cloud/self-hosted server (incl. OTA updates)

The CANedge1 and CANedge2 are 100% identical, except for the WiFi functionality in the CANedge2. Similarly, the CANedge1 and CANedge3 are identical except for the 4G LTE functionality of the CANedge3. Note also that the CANedge1/CANedge2 supports optional GNSS/IMU, while this is by default part of the CANedge3.

If you only need to collect your CAN data rarely and the device is physically accessible with ease, then the CANedge1 is typically enough. However, if you need to collect your data frequently and ideally remotely, the CANedge2/CANedge3 will quickly be worthwhile. In particular, if you need to collect data across a fleet of vehicles or machines, the CANedge2/CANedge3 are far more practical and cost effective.

A WiFi/LTE connected CANedge has the added advantage that you can fully automate your data collection, as well as your data processing workflow. For example, you can set up automated Python API scripts to modify your data, DBC decode it - and e.g. setup telematics dashboards. The CANedge2 is also easier to manage in the field as you can monitor the status via the CANcloud telematics platform and e.g. perform over-the-air configuration and firmware updates.

For use cases where a WiFi network is available, we recommend the CANedge2. If you need to upload data via 4G LTE (cellular), we recommend the CANedge3.

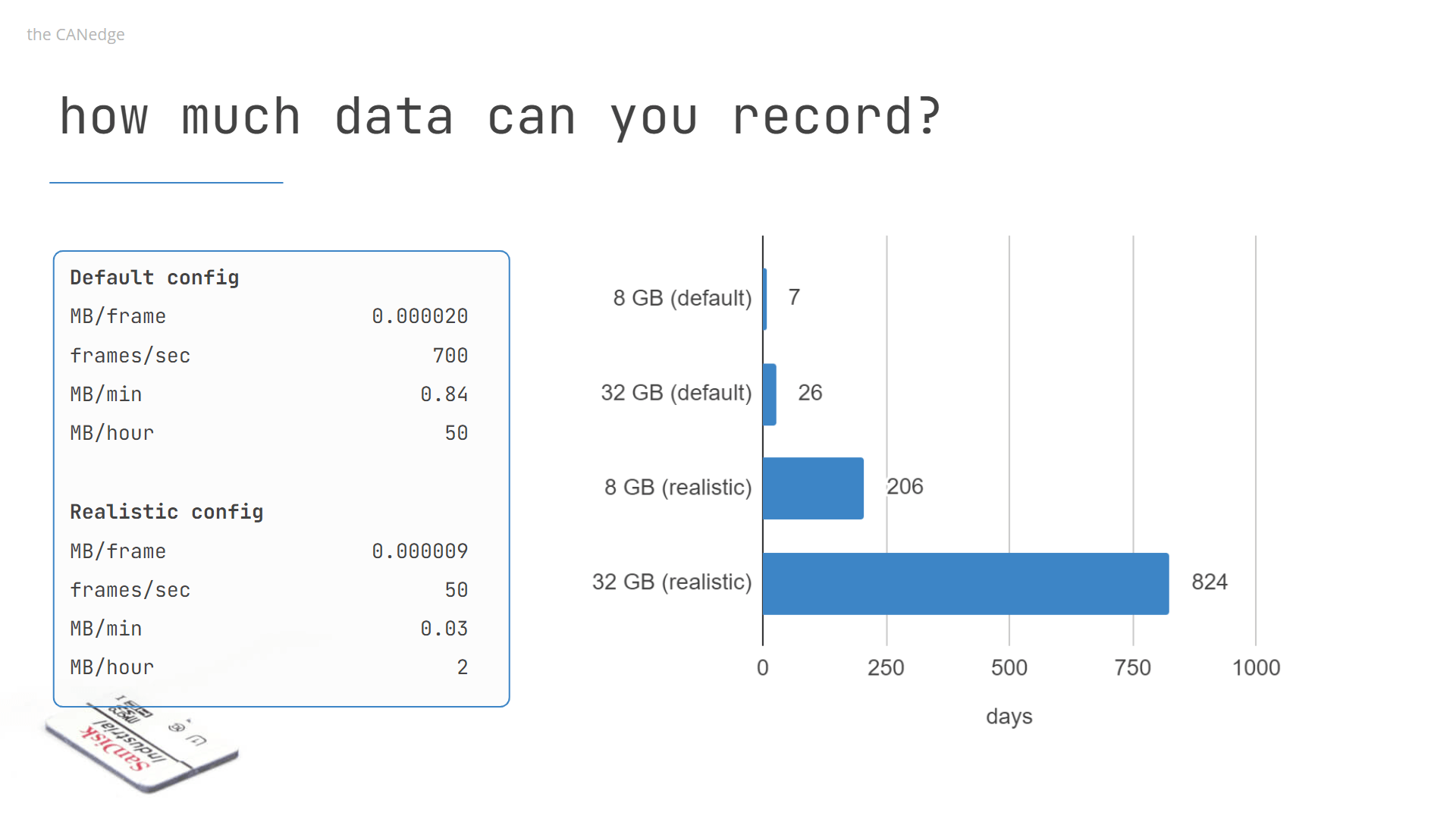

The size of a raw MF4 log files depends on the application - and how much data you wish to record.

The below overview shows a typical example for a heavy duty truck (J1939 data), exhibiting 700 frames/second. As evident, if you record everything, an 8 GB SD card will let you record data 24/7 for ~7 days - while the 32 GB would enable ~26 days.

However, the CANedge supports powerful options for optimizing the log file size. As a result, a more realistic scenario is shown below in which e.g. a 32 GB SD lets you record 800+ days.

Below we list some of the key features that let you optimize your logging:

- Compression: Enable compression to reduce the data size by 50-80%

- Filters: Specify which CAN IDs to record/ignore (via ranges and masks)

- Prescalers: Instead of recording frames at their 'raw' frequencies, you can customize the frequency by CAN ID

- Control signal: Specify when to start/stop logging based on specific CAN signal thresholds

If the SD is full, cyclic logging lets the CANedge CAN logger continue recording data by deleting the oldest log files first.

The CANedge1 CAN logger is superior when it comes to logging data to the SD card vs. the CL2000. However, the CANedge1 does not support real-time streaming via USB. For this type of use case, we would recommend e.g. the CL2000.

For an overall intro to CAN logging with the CANedge, see our 45 min webinar.

In the below, we outline the basics of how you can start logging raw CAN data:

- Connect the CAN logger to your CAN bus (optionally using our adapter cables)

- The device powers on, detects the bit rate and starts logging raw data to the SD card

- Disconnect the device, extract the SD and insert it into your PC

- Open the raw log files in e.g. the asammdf GUI/API for DBC decoding and visualization

For more details on getting started, see the CANedge Intro and Docs - or contact us if any questions.

The CANedge is designed to offer the best value/cost ratio in the 'pro specs' CAN/LIN logger market.

In particular, below factors differentiate it vs. similar devices:

- Pro specs: The CANedge offers specs on par with the best loggers available

- Compact: The CANedge is 50-80% smaller vs. similar devices

- Low cost: The CANedge is 50-80% lower cost vs. similar devices

- Easy-to-use: The device can be used out-the-box with no configuration

- FOSS: All software/API tools are 100% free and open source

- Interoperable: Open standards and tools enable integration into any system - with no lock-in

- Free support: We offer free best-in-class technical support

Don't take our word for it, though - check out our 50+ case studies from companies like VW, Siemens, Bosch, Cummins and more.

The above makes the device an excellent choice for e.g. automotive/industrial OEM engineers.

The CANedge1 CAN bus analyzer can record data from any high speed CAN bus application (ISO 11898-2). In practice, this includes raw data from almost all vehicles (cars, trucks, tractors, forklifts, buses, motorcycles, electric vehicles, ...) - as well as various production machinery, EV batteries/BMS and more. Most planes and boats also use CAN bus. In terms of protocols, this encompasses e.g. SAE J1939, CANopen, NMEA 2000, FMS, OBD2 and more.

For the specific case of OBD2 vehicle data, the CANedge1 can transmit up to 64 custom CAN messages periodically, which means it can be used as an OBD2 data logger. Note that you need to verify that your car uses CAN as basis for the OBD2 communication (this is the case for all US cars produced after 2008 e.g.). Also, note that all cars differ in the amount of OBD2 parameters they support - and the CANedge1 is of course only able to record the supported data.

For use cases where you need to add GNSS/IMU we recommend selecting a CANedge with built-in GNSS/IMU.

For other sensor inputs (temperature, analog, digital, pulse, ...), you can connect external sensor-to-CAN modules to the device. In particular, our CANmod sensor-to-CAN modules can be easily combined with the CANedge.

Specifically, the CANedge 2nd port can supply 5V DC to external modules - enabling easy installation. Data from the connected sensor-to-CAN modules is recorded in the CANedge log files along with data from the other CAN/LIN channels.

Consider e.g. our CANmod.temp temperature-to-CAN module or CANmod.input analog/digital/pulse to CAN module.

The CANedge requires the use of a specific industrial SD card model in order to guarantee the performance and power safety. You can select an 8 or 32 GB SD card as an option during check-out (or as a separate purchase).

You should not use 3rd party SD cards as these may result in data corruption and other forms of non-functional behavior.

Do you have any questions?

Contact us