Electric Vehicle Data Logger - Cloud Battery/BMS Telematics

Managing electric vehicle batteries is a challenge.

But, what if you could monitor your EV batteries across entire vehicle fleets

- directly from your own

cloud server?

Below we detail the EV industry, benefits of EV battery telematics and how to get started with the CANedge2 EV data logger, incl. setting up custom dashboards:

The electric vehicle battery (EVB) industry

EV batteries are growing fast.

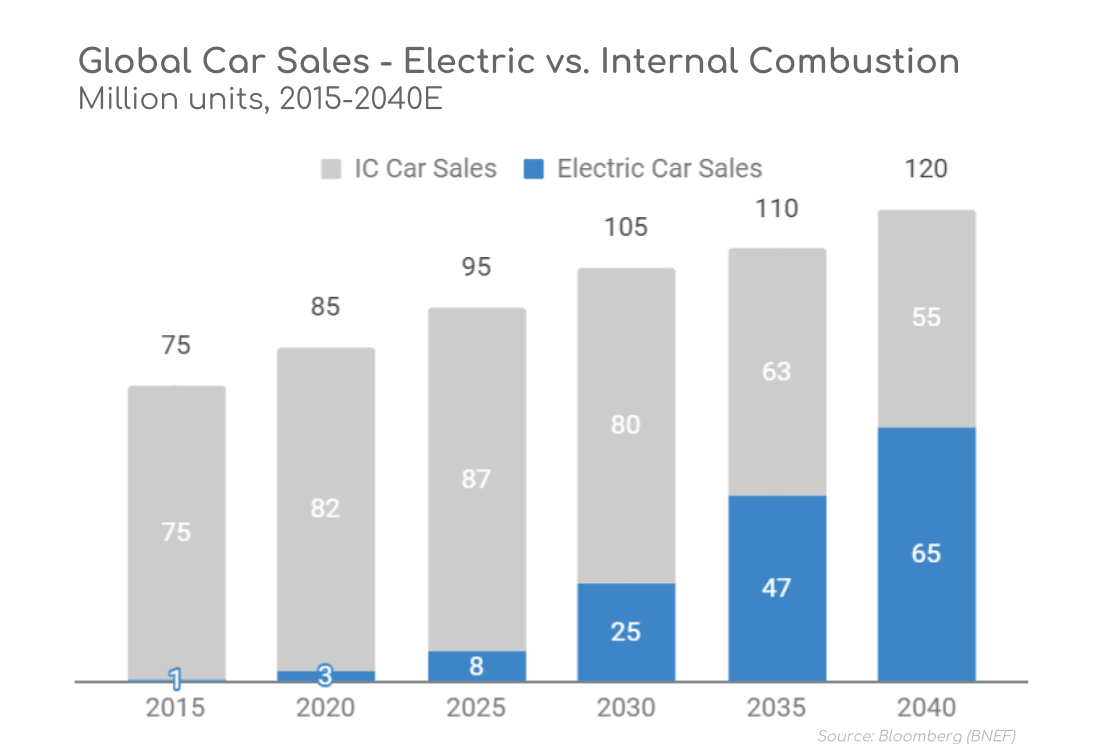

Over the next 20 year the EV battery market is expected to grow to $240-360 bn+ as electric cars target a 40-60% share of global vehicle purchases (up to 60+ million units/year) - and that's just within cars.

Below we outline facts & figures, EV types and EV battery types.

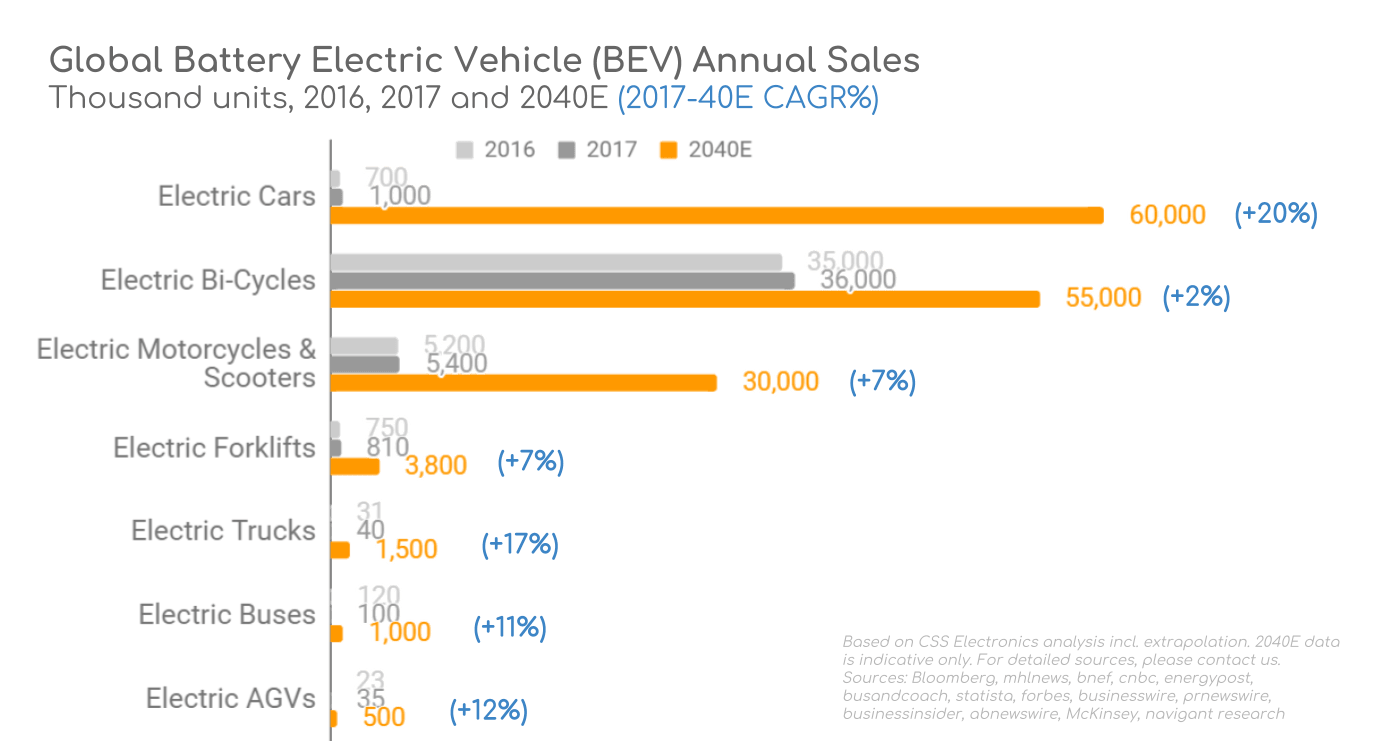

- Overall, electric car battery (EVB) sales are to grow from ~1 mn units in 2017 to ~60+ mn in 2040 (CAGR of ~20%)

- Further, electric two-wheelers (bi-cycles, scooters, motorcycles) may grow from 40 mn sold per year in 2017 to 85+ mn in 2040

- China is the #1 market with 70%+ global EVB market share by 2020

- EVs will account for 54% of new car sales by 2040 and 0.5 billion (33%) on-road light duty vehicles

- In 2040, EVs are to drive 67% of new car sales in Europe, 58% in US and 51% in China - today, they already drive 37% in Norway

- Growth is driven by a 70%+ price reduction per kWh for li-ion batteries (2010-17) - with another 70%+ expected by 2030

- 2018 top 5 lithium-ion manufacturers are Panasonic (33%), BYD (18%), LG Chem (17%), Samsung (9%) and Wanxiang (5%)

To understand the dynamics of the EV market, it's critical to segment by vehicle type.

The chart shows an estimate of current sales volumes by type, as well as an outlook towards 2040 for the main electric vehicle types (cf. below).

Overall, the global annual sales of these EV types may go from the current ~40 mn in 2017 to 150+ mn in 2040 - completely changing the automotive & two wheeler markets.

Below we briefly outline the main electric vehicle types:

|

|

Electric Cars: With the advances in lithium-ion batteries, electric cars are rapidly growing with e.g. 2017 Q3 showing a 63% growth YoY vs. 2016. By 2040, there'll be 560 mn electric cars on the road (33% of all cars) |

|

Electric Bi-Cycles: Already today a huge market of ~36 mn+ units sold globally (95%+ in Asia) - with e.g. 200 mn in use in China. Western EU see ~1.6 mn units sold annually, while North America is only at ~0.2 mn units per year |

|

Electric Motorcycles & Scooters: As for e-Bikes, electric motorcycles & scooters are biggest in Asia, though growing fast in India. Significant advances are made in the technology, boosting speed and range massively in recent years |

|

Electric Forklifts: Today, 60%+ of forklifts are electric (Class 1, 2, 3), up from 40% 30 years ago - with 600k+ electric units sold globally in 2017. This drives demand for lead-acid, lithium-ion and fuel cell batteries - and forklift telematics |

|

Electric Trucks: Electric trucks are expected to comprise 15% of all trucks by 2030 with e.g. the recent Semi launch by Tesla paving the way for eTrucks within also the heavy-duty segment |

|

Electric Buses: Buses go electric faster than other vehicles. In Shenzhen, China, all public buses are now 100% electric - counting a bus fleet of 16k+ for that city alone. Globally there are ~385k electric buses (99% in China) |

|

Electric AGVs: Electric Automated Guided Vehicles (AGVs) are portable warehouse robots. While still a small segment, the rise of e-commerce and Industry 4.0 may drastically boost their relevance and volume |

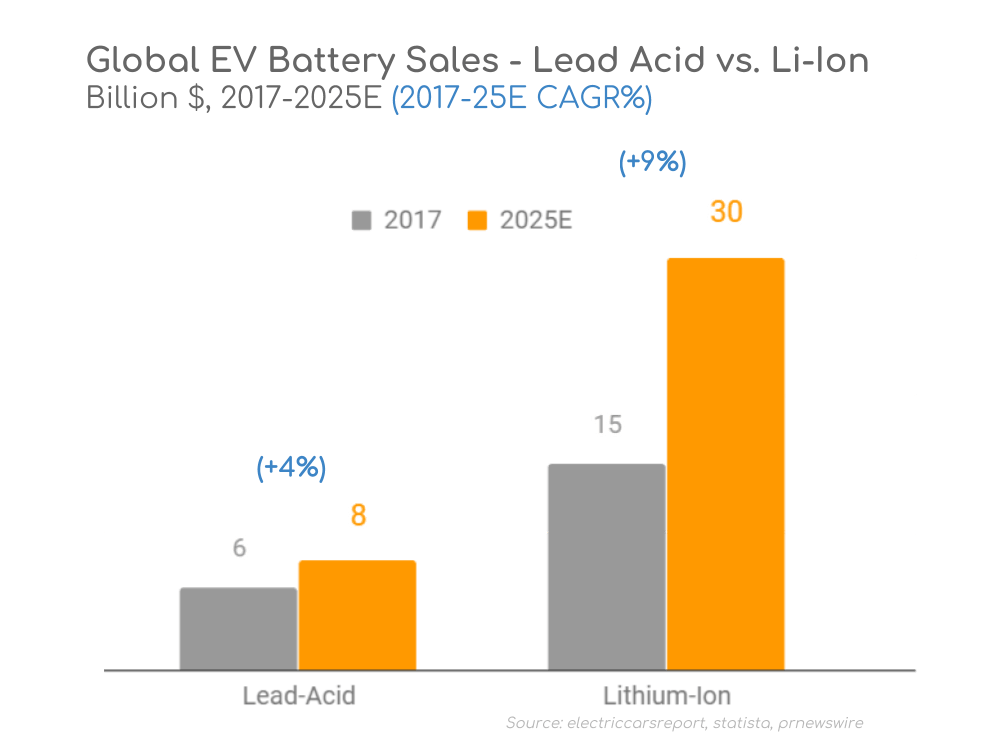

Various batteries are used in electric vehicle applications, but the most common are listed below:

Lead Acid: Deep-cycle lead acid batteries represent a fairly mature and low cost technology. However, they also require frequent replacement and have a very low energy density (30-40 Wh/kg). Use cases incl. forklifts, bi-cycles and cars.

Nickel-Metal Hydride (NiMH): Also seen as a mature technology, this EV battery type comes with a better energy density than lead-acid (30-80 Wh/kg) and offers exceptional life-time. However, they are less efficient and have a number of other downsides.

Lithium-Ion (Li-Ion): Today, li-ion batteries are used in most EVs due to their 200+ Wh/kg density and strong efficiency specs. Recent variants reduce costs massively, while boosting lifetime towards 10-40 years.

Fuel Cells: Fuel cells play an increasing role in powering e.g. electric forklifts, with big players like Walmart and Amazon making the shift. They replace or work with a rechargeable battery and are emission-free, generating only heat and clean water. Advantages include faster recharging, lighter infrastructure, temperature stability and better life-time costs.

The challenge with the BMS

The Battery Management System (BMS) serves as the 'brain of the battery' - ensuring efficient & safe operation.

However, the BMS is offline with zero data storage - making it difficult to manage batteries at scale and remotely.

The solution is EV battery telematics aka 'connected batteries' - enabled through recent mega trends (see below).

The BMS is an electronic system that integrates with rechargeable batteries to monitor critical data parameters.

These include e.g. state, voltage, current and temperature.

Based on the data, the BMS performs vital tasks:

- Keeping the battery inside it's safe operating area

- Monitoring & reporting the battery state (SoC, SoH, ...)

- Balancing cells to ensure a similar state of charge

- Prolonging the life of the battery

- Communicating with e.g. chargers or external devices

Example: The role of BMS in charging

In lithium-ion batteries, overcharging can lead to overheating - potentially resulting in catastrophic events. Conversely, discharging the battery below e.g. 5% capacity can lead to permanent capacity reduction. In both cases, the BMS manages the charge to avoid thresholds being passed. An example of a more advanced use of BMS is in "intelligent batteries". Here, the BMS provides data to an "intelligent charger" on the battery's specs, condition and usage history - allowing the charger to perform optimal charging.

In automotive context, the BMS needs to be able to communicate with other sensors and ECUs in the vehicle. As CAN bus is the standard in automotives, it's also the de facto standard for EV batteries. As such, it's possible to record data from the BMS of most EV batteries using a CAN bus data logger. In turn, this also enables the use of IIoT CAN bus data loggers with WiFi for e.g. forklift telematics, AGV telematics and other BMS-data-to-cloud solutions.

Specifically, batteries often rely on the CAN bus protocols SAE J1939 or CANopen - providing data on a range of parameters, e.g. temperature, pack voltage, cell voltage, current, errors, SoC. In general, EVs will require more data and as such, CAN FD will also play a core role in enabling the future growth.

Rise of EVs

As EVs rapidly grow towards 2040, there will be a need for integrating battery telematics into commercial vehicle fleets - across trucks, vans, buses, forklifts, AGVs and more. As this market matures, so will electric vehicle telematics

150+ mn

EVs by 2040

(vs 40 mn in 2017)

Rise of Cloud

Like vehicles, batteries provide tons of data that need storage and fast processing - but with the rise of cloud servers, this becomes increasingly simple & low cost. Cloud computing also enables more advanced BMS methods

$300 bn

public

cloud market in 2021

(vs ~150 bn in 2017)

Rise of IoT

Collecting battery data via WiFi / 4G has previously been costly and difficult. However, the rise of the Internet of Things (IoT) now also brings low cost CAN bus IoT devices that easily enable the transfer of the battery big data

5+ bn

B2B IoT devices by 2020

(vs ~2.5 bn in 2017)

Rise of AI

The use of Artificial Intelligence (AI) for EVBs has been impossible on the existing BMS systems - but with the full set of big data in the cloud, next level battery optimization will be possible - and key to stay competitive

50%+ CAGR

in AI enterprise market

($1 bn in '17 to $30+ bn in '25)

Or, as stated in the below article published in the Power and Energy Magazine IEEE (2017):

"The continuing proliferation of and advances in information and communication technologies, development of powerful cloud computing capabilities, and a growing Internet of Things will significantly enhance or even transform the concept of battery management, as modeling and control of thousands of cells in large-scale battery storage will become easier."

— Hu, C. Zou, C. Zhang, Y. Li, "Technological Developments in Batteries: A Survey of Principal Roles, Types & Management Needs"

Top 4 benefits of EV battery telematics

The CANedge2 is used in many battery telematics use cases - below are the top benefits mentioned by end users.

Improved battery charging & life

Monitoring State of Charge (SoC) remotely in near real-time enables e.g. warehouse managers to optimize charging, reducing downtime and improving battery life

Fewer EV battery breakdowns

Using predictive maintenance, end users can auto-process e.g. battery pack temperatures and currents to minimize the risk of e.g. lithium plating or thermal runaway

Warranty & claim optimization

EV battery breakdowns can be extremely costly. Storing all historical operational data in the cloud can be key in insurance/warranty cases - and simplifies compliance

Faster development & diagnostics

To minimize time to market, OEM engineers can collect field usage data remotely to diagnose issues faster. Further, OEMs can manage batteries remotely via OTA updates.

Which benefits are relevant to your EV/battery use case? Reach out for free sparring!

Contact usWhy use the CANedge EV logger?

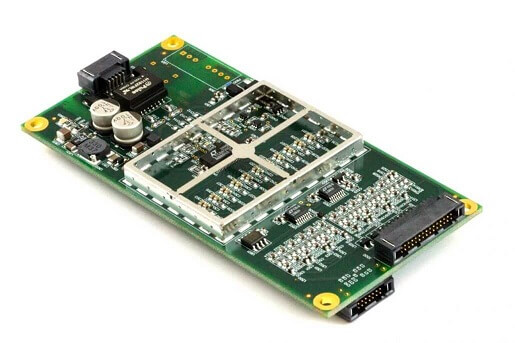

The CANedge CAN bus data logger offers optional GPS/IMU, WiFi and/or 3G/4G - ideal for EV fleet telematics:

Log data out-the-box. Standalone. Link your vehicle to your server in <2 minutes

Extractable 8-32 GB SD. 2xCAN/LIN. CAN FD. Zero data loss. 50 μs RTC. Error frames. MF4

Only 8 x 5 x 2 CM. 100G. Robust alu enclosure. 5+ LEDs. Configurable 5V power out (CH2)

Built-in GPS/IMU. 3x accuracy via sensor fusion. Position, speed, distance & more

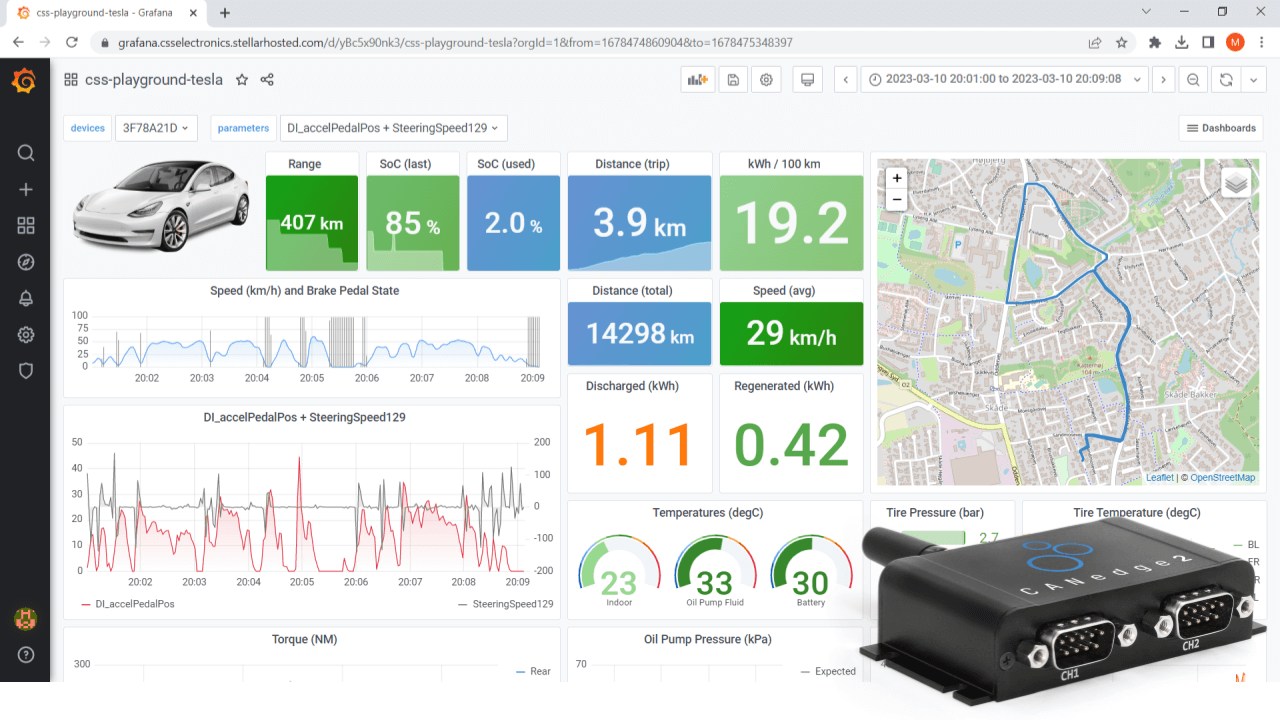

Software example: Electric vehicle dashboards

With the CANedge, you can easily set up free, custom browser dashboards for visualizing your EV data and setting alerts.

You can also combine your EV data with GNSS/IMU data by using a CANedge incl. GNSS/IMU.

Check out the online playground - or learn more in our intro!

playground dashboard introEV battery telematics use case examples

Below we provide practical examples of how the CANedge can be used for logging electric vehicle data.

Warehouse EV fleet management

Need to setup AGV/forklift telematics in a warehouse?

The CANedge2 can be used for warehouse telematics. The device is easily installed in each asset and can be configured to connect to 1-5 local WLAN routers in the warehouse. Data can be auto-pushed to a local server or a cloud server for processing. If the devices are out-of-range of the router, data is simply buffered on the SD cards. A battery OEM can e.g. use this to monitor SoC, predict breakdowns, offer remote forklift battery management and more. Further, devices can be easily managed over-the-air via the open source telematics platform.

On-the-road EV telematics

Need to monitor & optimize an EV fleet in near real-time?

For 'on-road' near-real-time upload of data from EV cars, the CANedge3 can upload data via 3G/4G using your own SIM card. The CANedge3 is able to log both CAN/OBD2/UDS data (incl. CAN FD data) in parallel across two channels. Data can be encrypted on the SD card and uploaded via HTTPS for security and GDPR/CCPA compliance. The device also records internal GNSS/IMU data such as position, speed, trip distance, acceleration and more in timesync with your CAN/LIN data.

Case study: EV telematics

Learn how Antu Energia uses the CANedge2 to remotely collect CAN/J1939 from heavy duty trucks and buses. Data is uploaded via a 3G/4G access point to their own AWS S3 cloud server for use in e.g. analyses, dashboards and script automation.

"CSS Electronics devices/software have been an absolute cornerstone to the success of many of our projects - and the customer service is one of the best I've ever had"

full case study 100+ case studies

FAQ

Is the asset CAN based?

Practically all EV batteries are based on CAN bus (similar to all vehicles). If your battery is CAN based, you'll be able to record data using a standard CAN bus data logger. We always recommend verifying the specific bus type with technical staff.

How to convert data?

Raw CAN data has to be "scaled" to become readable. To do so, you'll need a 'conversion rule database' (aka DBC file). If you're a battery OEM, your technical staff will have the conversion rules - if not, you may reverse engineer this or get it from the OEM. For EV cars, you may be able to log OBD2 data.

How to collect data?

The CANedge comes in different variants, tailored to match your specific preferences. The CANedge1 lets you collect data offline via the SD card. The CANedge2 enables automatic upload of data by connecting to WiFi access points. Finally, the CANedge3 lets you upload data via 3G/4G - making it ideal for data collection from mobile vehicles. If in doubt what is the best fit, contact us.

As mentioned above, most electric vehicles and battery management systems are CAN based. If you are the OEM, you'll also have the decoding rules for scaling the raw CAN bus data to human-readable form.

In some cases, however, you may want to record electric vehicle data - but you you do not have the decoding rules. Below we outline the typical options you have in this scenario:

- Contact the OEM: In some cases you may be able to request a DBC file and/or PDF with decoding rules from the OEM. This is often possible when working with smaller OEMs and specialized EV products. However, you'll rarely be able to get this information for e.g. private electric cars.

- Research online: You may be able to find databases where others have found decoding rules for e.g. electric cars (see below)

- Reverse engineer the data: As a final resort, you can attempt to use a CAN bus sniffer tool to reverse engineer the CAN bus data - though it's difficult if you need a large number of parameters

By researching online you'll often be able to find e.g. DBC files (CAN databases) containing decoding rules for electric car brands. DBC files can be loaded by most CAN software tools for data decoding, including e.g. the free CAN software asammdf for use with the CANedge.

Typically, these contain EV parameters like State of Charge (SoC), State of Health (SoH), battery current, voltage, temperatures, cell voltages, charging status etc. Below we've listed some of the popular open databases:

- OpenDBC: CAN DBC files for brands like Nissan Leaf (2018), Tesla and more

- Tesla Model 3 & Y: DBC file for Tesla Model 3 and Tesla Model Y

- OBD Dash: Proprietary OBD2 PID info on Mitsubishi, Renault, Subaru, Opel, Hummer and more

- Kia Soul: Google sheet containing decoding information for the Kia Soul EV

- Open Garages: Collection of links for decoding info, incl. Prius and more

- EV PID collection: Extended OBD2 PIDs for EVs, incl. Hyundai Kona, Ioniq EV, Kia Niro, Optima, Ray, Soul EV and more

- Nissan Leaf DBC: Nissan Leaf EV DBC files for use in some Leaf EV models (but not 2019+)

- Renault Zoe: CSV with decoding info for the Renault Zoe EV

Note that some of these do not directly provide DBC files with the decoding rules (for example the 'EV PID collection'). This is typically the case if the decoding rules originate from a tool that does not use DBC files for decoding. In such a case, you can however easily create your own DBC file with the relevant signals. For regular CAN data, this is typically straight-forward. For UDS decoding rules, we suggest you check out our github API examples for a sample DBC for the Hyundai Kona EV.

It is important to note that the way you collect electric vehicle data may differ significantly by car brand/model/year.

Broadcast vs requests: In some electric cars, you'll be able to directly connect via the OBD2 connector to access broadcast raw CAN bus data, containing signals like SoC. However, in other cases you'll need to 'request' the data from the electric vehicle via UDS requests (Unified Diagnostic Services) - see e.g. our github API examples. In the API example, we have configured a CANedge2 to send transport protocol UDS requests to a Hyundai Kona EV via the OBD2 connector. We used the EV PID collection above as basis for creating a DBC file with extended multiplexing, for use in decoding the UDS responses via the CANedge Python API.

Rise of UDS: The exposure of UDS requesting rather than raw CAN bus data appears increasingly popular in electric vehicles. For example, the Nissan Leaf models up to 2018 broadcast SoC as part of the raw CAN data available via the OBD2 connector. However, since 2019 the models do not broadcast any CAN bus data via the OBD2 connector - though the Nissan Leaf responds to UDS requests in similar style to the Hyundai Kona.

Contactless reading and EV-CAN: It is also possible to access the raw CAN bus data from an electric vehicle via other methods than the OBD2 connector. For example, you can use a contactless CAN reader to log data directly from the raw CAN low/high wiring harness. Sometimes it is also possible that two CAN buses are used in an electric vehicle, in which case you may log both via a modified OBD2 adapter cable as in our Nissan e-NV200 case study. The 'extra' CAN bus exposed via the OBD2 connector is sometimes referred to as EV-CAN.

Logging data from electric cars can be complex, but you're always welcome to contact us for sparring on your use case.

Once you've reviewed the above, we propose below next steps to get started:

- Select a 'pilot kit' to get started - e.g. the CANedge2 (8GB) + a suitable adapter cable

- Design a small proof-of-concept (incl. a very narrow use case)

- Do a PoC on data collection, conversion & data processing

- Develop a bare-bones application script in the cloud to solve a basic pain point

- Scale the PoC to a full segment (BU, country, warehouse, ...) and review

- If successful, scale up step-by-step by adding more devices and more automated scripts

Ready to start your electric vehicle telematics pilot?

Get your CANedge2 today!