NMEA 2000 Data Logger for Engine Diagnostics

Case Studies / Honda Marine

Honda Marine

Honda Marine distributes a full line of four-stroke marine engines ranging from 2 to 250 horsepower. Honda Marine is part of Honda's Power Products division.

What problem did you solve?

We need to solve two primary challenges with the CANedge1 in our NMEA 2000 networks:

First, we use the CAN bus data logger to assist us in remote diagnostics. Essentially, when we are unable to get a qualified technician on-site, we can instead send the data logger to the vessel to make recordings. The resulting log files can then be sent back to the engineering team for analysis. This is only possible because the device is standalone and easy to install.

Second, we use the data loggers to capture difficult-to-obtain data. There are occasionally instances where an intermittent issue persists, yet it's practically impossible for the technician to replicate it. With the CANedge1, we can instead simply connect the data logger to the vessel. The data logger can record for days or weeks until the issue occurs again - and when it does, the data logger is there to record the conditions for analysis.

We perform the data logging across a number of applications. Most common are remote vessels. These are typically harder to find technicians to service. The last boat we used it on was a landing craft, which was used to move construction equipment to remote areas.

"The CANedge1 is a compact and powerful tool that allows us to quickly and easily capture NMEA 2000 data"

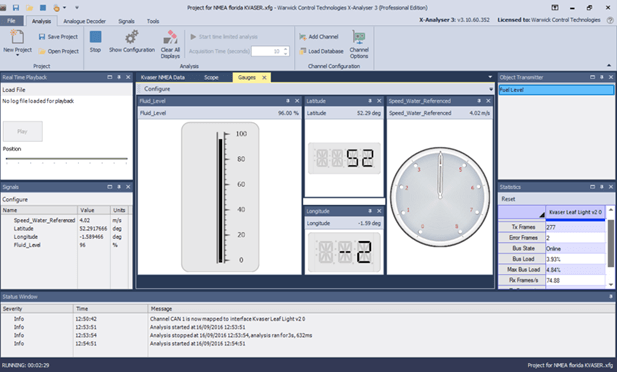

The CANedge MF4 logs can be converted to e.g. Vector ASC for integration with

tools like Warwick's X-Analyser

The CANedge MF4 logs can be converted to e.g. Vector ASC for integration with

tools like Warwick's X-Analyser

How did you solve it?

When a situation is identified in which a data log could assist the diagnosis of an issue, one of our engineers will ship the data logger to a vessel for installation. Once the unit is received at the vessel by the client, our engineer will remotely assist the client with the installation (which typically only takes minutes). We then ask the client to operate the vessel to duplicate the complaint, multiple times if possible. Once the data has been captured, the client ships the recorder back to our office.

Here, our engineers use the CANedge MF4 converters to convert the log files into Vector ASC. Subsequently, the files can be loaded in Warwick's X-Analyzer tool, which the team uses to filter the NMEA 2000 data and identify the conditions surrounding the complaint. This data analysis can then be used to form a plan to effectively resolve the complaint.

What benefit has this led to?

In the past, prior to using the CANedge1, we would sometimes have the technician make multiple trips back to a vessel to duplicate an issue - that was not a very efficient use of our resources (and of course frustrating for the customer). With the CANedge1 this can be avoided. Further, it can often be difficult to get accurate data from a customer - whereas logging the NMEA 2000 data directly offers an objective recording of the conditions. The CANedge1 has been a valuable tool in helping us get our customers back onto the water as quickly as possible.

Why did you choose the CANedge1?

We selected the CANedge1 based on the price and availability. I did not do a lot of research before I bought it because of the price, it was low enough were I could just buy it and try it out and fortunately it worked well so we continue to use it.

— Ryan Martin, Sr. Applications Engineer, Honda Marine

Ready to log your NMEA 2000 data?

Get your CANedge today!