Reverse Engineering Proprietary J1939 PGN & SPN Data

Case Studies / DDR

DDR Marine Projects & Engineering

About: As an independent entrepreneur, Daan de Roos focuses on technical aspects of the propulsion installations of all types of (commercial) ships, work boats and yachts

What problem did you solve?

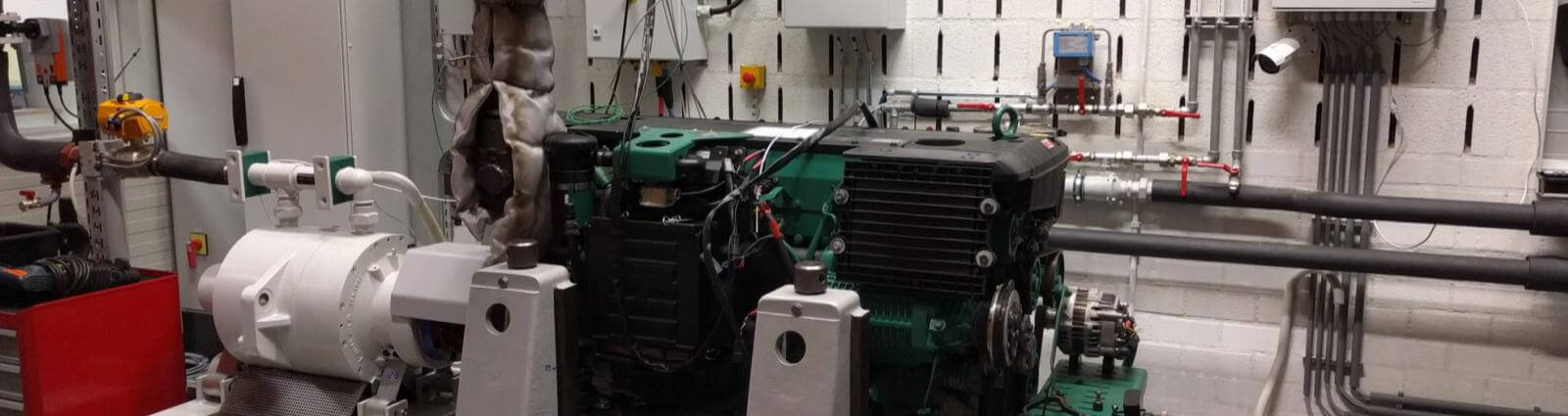

We needed to build a test stand for maintenance and power testing of machine and boat engines, in particular Volvo Penta EVC controlled engines. A requirement was to add a simple start, stop & (de-)accelerate system for the various engines. One method for controlling the engine was via CAN bus (J1939). However, some J1939 parameters were proprietary - CAN bus reverse engineering was necessary

How did you solve it?

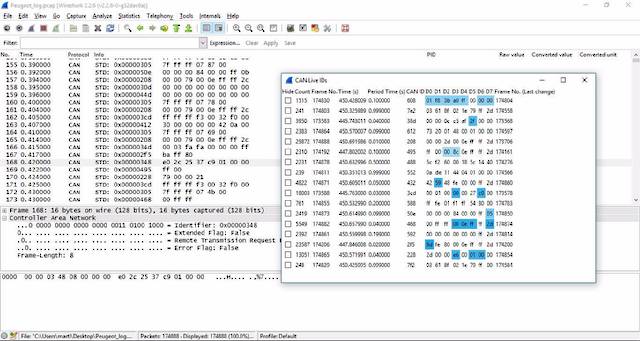

We used the CLX000's logging function and the Wireshark reverse engineering plugin to read, log and label proprietary J1939 parameters. This in turn enabled direct control of the machine via CAN bus and allowed use of Horiba software / hardware

What benefit has this led to?

The result was a CAN bus communication system for various electronically controlled motors. Further, mechanical motors are controlled via an actuator. The actuator was also controlled via CAN bus from the Horiba software 'Stars'Why did you choose the CLX000?

Strong price and quality - and it's easy to use with both stand-alone logging features and real-time streaming via Wireshark [see also the SavvyCAN integration].

"The CLX000 worked perfectly for reverse engineering proprietary J1939 data"

— Daan de Roos, owner of DDR Engineering & Marine Projects

Bonus: Check out Daan's own blog post on this use case for more details.

The CLX000 - CAN bus data logger & interface

The standalone CLX000 lets you both log and USB-stream CAN data (with 100% free software) - learn more:

Ready to log your J1939 data?

Get your J1939 logger today!