Mining Telematics - J1939 IIoT Logger [+Free Dashboards]

Looking to set up your own mining fleet management system?

In this practical step-by-step guide you'll learn how to use the CANedge2 IIoT J1939 logger in underground mining telematics - from raw data to mining dashboards.

Top 4 benefits of mining telematics

Our users within mining (contractors/OEMs) generally quote 4 key productivity benefits of mining telematics.

You probably know these, so we'll twist it by linking these with examples of relevant J1939 data parameters:

Utilization & payload

How many tons are moved? By which vehicles? When? How many hours did a vehicle run/idle last month? Knowing the "pulse" of your machines and the usage efficiency is vital to a variety of use cases

Engine Hours, Engine Speed, Payload Weight Sensor Status

Fuel cost reductions

How much fuel is used per vehicle? By driver? By period? By correlated parameter? Monitoring fuel at scale can vastly improve your TCO (total cost of ownership) - and help prevent e.g. fuel theft

Fuel Rate, Fuel Level, Tire Pressure, Vehicle Speed

Predictive maintenance

Is a vehicle going to break down next week? Mining vehicle downtime is extremely costly - and even very basic predictive maintenance can make a huge difference to ensuring your asset health

Diagnostic Trouble Codes (DTCs), Temperatures

Blackbox & diagnostics

Does a vehicle exhibit a rare issue? Is monitoring required for insurance / compliance? By logging data continuously, you'll be able to review past events and diagnose issues much faster

Multiple J1939 parameters with focus on e.g. outliers

Which benefits are relevant to your mining use case? Reach out for free sparring!

Contact usThe challenge with traditional mining telematics

Most companies attempt to harvest these benefits - but many fail due to below challenges.

Too complex

Signed up for an expensive E2E telematics platform - but you only use 10% of the features? Your solution scope must match internal capabilities. If not, costs will drastically outweigh the value

No 3G/4G coverage

Do you have good cellular connectivity in your underground mine? If not, this disqualifies most traditional telematics dongles as they rely on consistent 3G/4G coverage to push data

No data ownership

Tired of generic PDF reports? What about vendor lock-in? As an end user, you often get one-size-fits-all dashboards or aggregated low resolution data - blocking opportunities for tailored use cases

Security risks

Are you OK sending your CAN data to a server that you do not own? Is it encrypted? What if a dongle is compromised? Many telematics providers do not fully address cybersecurity

The CANedge2/CANedge3 provides an alternative mining fleet management system:

Start simple

It is extremely simple to get started. Add to that the benefit of zero software/API costs, zero monthly fees and zero vendor lock-in. Together, these factors let you scale up both your volume and solution scope at your own pace. At the same time, the versatile configuration and open software/API suite allows the device to scale with your ambitions.

Flexible WiFi/LTE

The SD card + WiFi or 3G/4G combo is ideal for underground mining. The device logs data to the extractable SD card when offline, ensuring zero data loss. When a CANedge2 is in range of one of up to 4 WiFi access points it will push the data to your server. In turn, the CANedge3 can use 3G/4G when outside underground mines to offload accumulated data. This allows for effective telematics - even with sporadic coverage.

You own the data

You have 100% control of your data: The device lets you customize your data flow - e.g. message filters, data compression, triggers and transmit lists. Further, you can easily process incoming data via open APIs - e.g. to create mining fleet dashboards or transform it into relational databases (SQL, Historian, PostScript) for your BI system. All data is owned by you.

Top security

Finally, the security is designed to be best-in-class: Data can be encrypted on the SD and sent securely via HTTPS to your server. Your WiFi/SIM/server details can be encrypted on the SD card. Further, configuraton & digitally signed firmware can be securely updated over-the-air across your fleet.

The CANedge J1939 mining data logger

The CANedge CAN bus data logger offers optional GPS/IMU, WiFi and/or 3G/4G - ideal for mining fleet telematics:

Log data out-the-box. Standalone. Link your vehicle to your server in <2 minutes

Extractable 8-32 GB SD. 2xCAN/LIN. CAN FD. Zero data loss. 50 µs RTC. Error frames. MF4

Only 8 x 5 x 2 CM. 100G. Robust alu enclosure. 5+ LEDs. Configurable 5V power out (CH2)

Built-in GPS/IMU. 3x accuracy via sensor fusion. Position, speed, distance & more

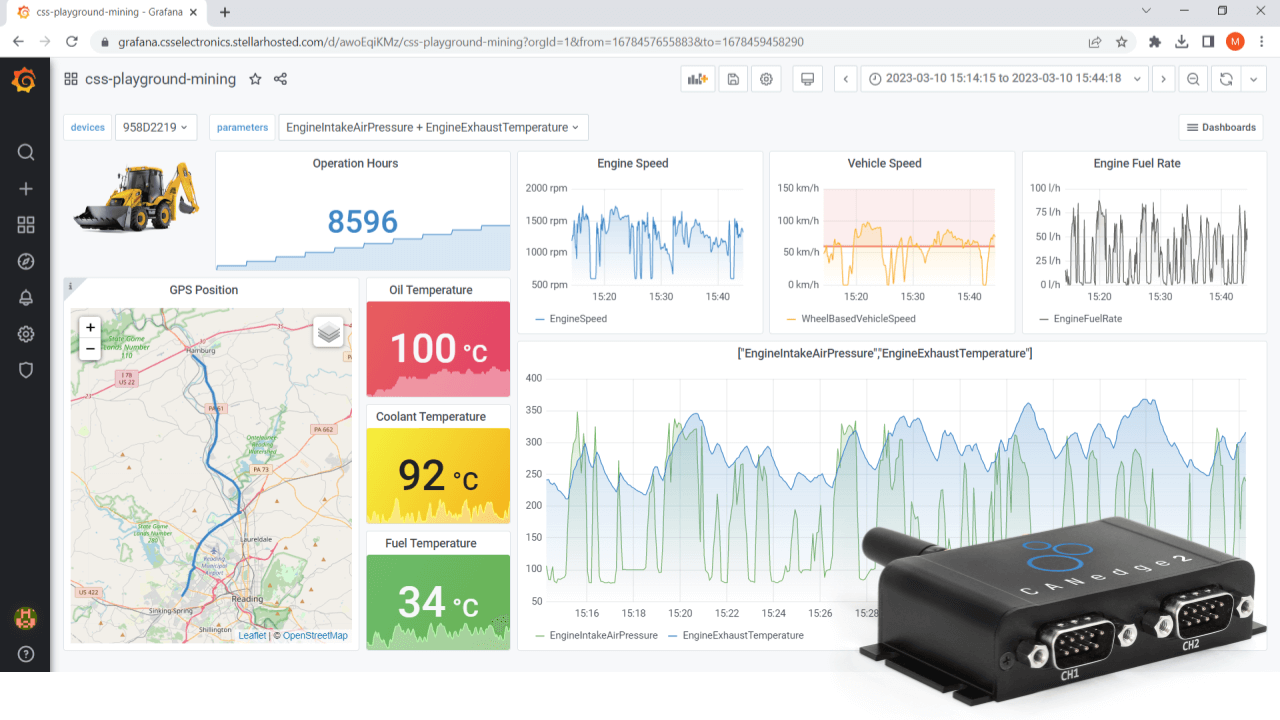

Software example: Mining dashboards

You can easily set up free, custom mining dashboards to visualize your mining fleet data and set data alerts.

You can also combine your J1939 data with GPS/IMU data by using a CANedge incl. GNSS/IMU.

Check out the online playground - or learn more in our intro!

playground dashboards introCase study: J1939 telematics

Learn how one of our larger OEM customers use the CANedge2 to collect CAN bus data from heavy machinery in the field - and use it to perform simple automated predictive maintenance.

"Both the hardware and support from CSS Electronics have been outstanding!"

full case study 50+ case studies

Mining telematics: Step-by-step guide

In the following section, we assume that you're an engineer at a mining OEM/contractor.

You've been tasked with setting up automated data acquisition across a range of vehicles - and below we help you get started.

#1 Consider your data flow

It's a good idea to consider your data flow up front - below we outline three popular setups:

Underground SD + WiFi

Here, the CANedge2 connects via underground WiFi access points, sending logged data from the SD card when in WiFi range. Ideal for mining vehicles that primarily operate below ground.

Above ground WiFi/LTE

Alternatively, your CANedge2 can upload data via WiFi when arriving at a maintenance site. Or, you can use the CANedge3 to upload via 3G/4G when above ground. Useful if you have no underground WiFi network.

Mix

The device supports 1-4 WiFi access points. You can thus configure a CANedge2 to both upload via an underground WiFi network and via a 3G/4G USB router for maximum coverage.

#2 Select your hardware

Next, you need to select a hardware bundle for your initial pilot test.

To get started, we recommend getting a CANedge2 or CANedge3 along with a set of adapter cables. The most common mining vehicle adapters are our J1939-DB9 and CAT-DB9 adapters. If you have experience recording CAN data directly from the wiring harness, you can also consider our contactless CAN readers. For details, see our products page.

For some use cases you may simply need to log CAN data to an SD card. For example, if your aim is to only analyze data if an issue occurs or as part of dispute handling, a CANedge1 dual CAN logger will suffice. The CANedge1 is identical to the CANedge2/CANedge3, except that it does not support WiFi/LTE. If you're in doubt which option is best for your use case, contact us.

In most heavy duty vehicles, you'll find a J1939 deutsch 9-pin connector in the cabin (sometimes behind a panel). If you see this, check if the relevant pins are available (power, ground, CAN low, CAN high). If so, you'll be able to use a DB9-J1939 adapter.

In CAT engines, you'll often see a 9-pin connector with a different pin-out. In this case, contact us as we may be able to supply a custom DB9-Deutsch-9-pin (CAT) cable for this. You will not be able to use a DB9-J1939 adapter in a CAT engine.

Other connectors exist - here we recommend to identify the pin-out (e.g. from a spec PDF or via an oscilloscope). After that, you can find an open-wire matching adapter and create your own custom cable. Optionally use our DB9-generic adapter.

In some cases, you may prefer to log data directly from the CAN wiring harness. In this case you can use a CANCrocodile adapter to snap onto the CAN L/H.

An example of a Sandvik mining truck connector interface.

In some heavy duty mining vehicles like dump trucks, excavators, drillers etc you may have two separate CAN buses, each containing separate data parameters. The CANedge lets you record data from both CAN buses with synced timestamps into the same log file. In this case, you'll of course need a suitable adapter cable for both CAN buses.

Note that often one CAN bus will be J1939 based, while the other may e.g. be CANopen based - with the latter being predominantly proprietary in nature. In such cases, we would recommend to start with the J1939 data and review whether data from the 2nd CAN bus is needed - and if so, reverse engineer the relevant parameters.

Another typical use case for multiple CAN buses is logging J1939 vehicle data via one channel - while using the 2nd channel of the CANedge for additional sensor modules. Examples include tire pressure sensors, payload sensors, hydraulic sensors, analogue/digital inputs, GPS & accelerometer, fuel sensors etc. Assuming you have sensor modules that broadcast their data via CAN, you can combine one or more of these into a single CAN bus and feed the data into the CANedge2 channel 2 port.

The CANedge2 can connect to your existing WiFi access points in e.g. an underground mine to upload data.

However, it is also possible for the device to upload data via a cellular hotspot like a USB 3G/4G WiFi router. This can be useful if you e.g. wish to upload data from a truck when it resurfaces from your mine and regains cellular connectivity.

However, if your aim is to purely upload data via 3G/4G, we instead recommend using our CANedge3, which is superior for this use case.

In some cases, you may need to add GPS tracking as part of your mining fleet management system and mining dashboards. There are different ways of achieving this. Some mining trucks have a built-in GPS module that broadcasts GPS data via the CAN bus. If the data is encoded as per the J1939 protocol standard, you can easily decode this GPS data to human-readable form and use it along with other CAN signals.

If no built-in GPS is available, you can use a CANedge incl. GNSS/IMU.

#3 Log your first data

To log raw vehicle data to the SD card, simply connect the CANedge to your vehicle and later disconnect it.

If you convert the data into CSV using our MDF4 converters the result may look as below raw J1939 truck data:

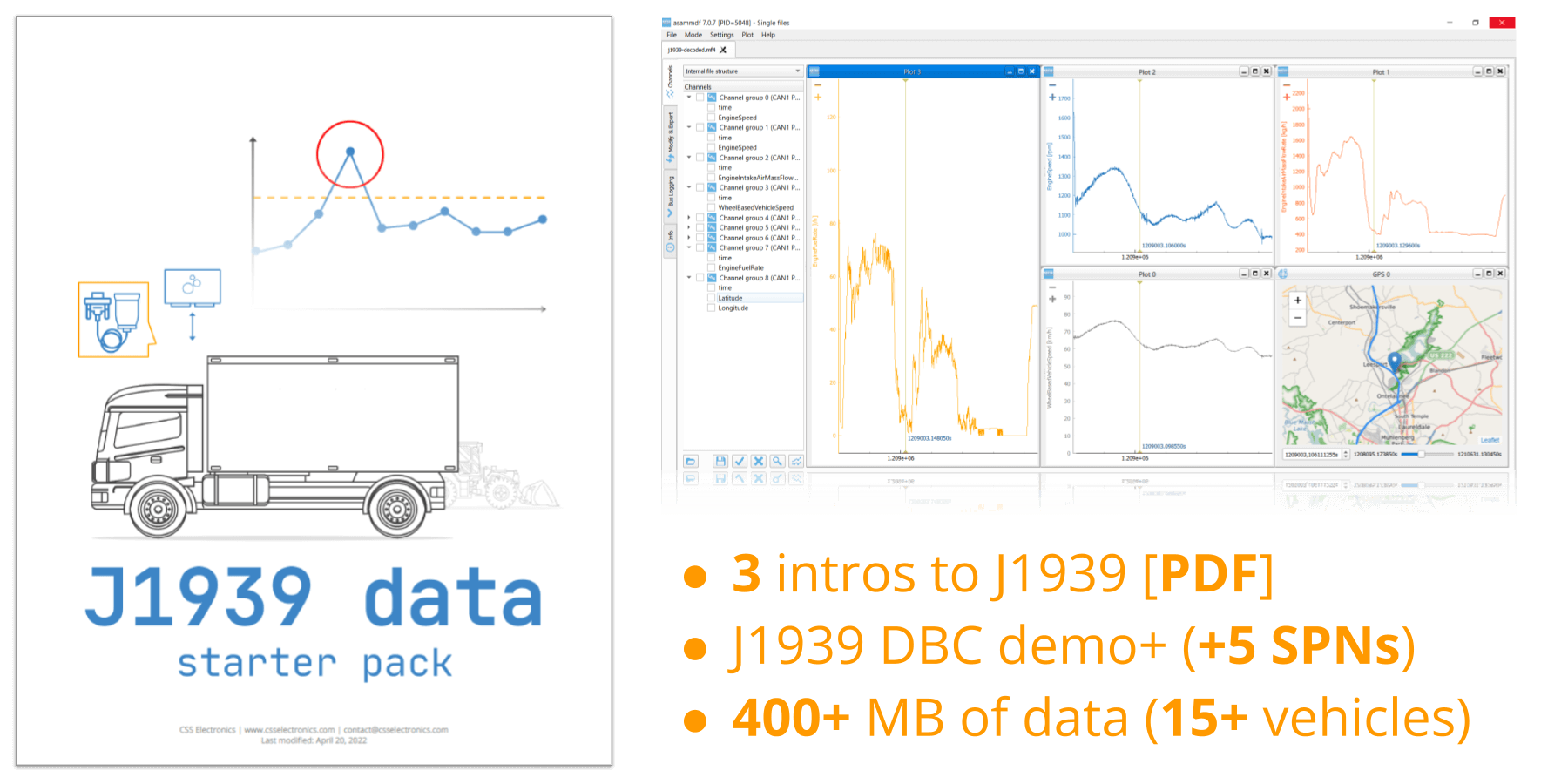

Get your 'J1939 Data Pack'

Want to try working with real J1939 data?

Download your 'data pack' incl. our J1939 DBC demo (incl. 5 extra SPNs) and 400+ MB of J1939 data across 15+ vehicles!

#4 Transfer data to your server

Once you've confirmed that you can log data as expected, you can set up the connectivity and server flow.

Once set up, you can test if your device correctly uploads data by logging into your server via our free open source CANcloud tool. CANcloud is basically a 'cockpit' for your deployed devices.

Don't worry if you've never set up a server before.

We provide step-by-step guidance in our get started docs. For example, you can set up an AWS S3 cloud server in <5 min. You then simply add your WiFi/SIM/server details to your configuration file - and you're ready.

#5 Process your data

Once you've verified that your data is coming into your server as expected, you can start processing the data.

For ad hoc analysis (e.g. diagnostics), you can load the log files in e.g. asammdf to DBC convert and plot it. Or, you can convert the data to e.g. Vector ASC and analyze it via CANalyzer.

You can also automate your processing via the free CAN bus Python API.

A DBC file is a database of conversion rules - it's a text file that details how to go from raw CAN data to human-readable data.

Most mining vehicles are heavy duty and communicate data via the J1939 protocol. As such, you can use a J1939 DBC file to convert the raw data into human-readable form. It differs by vehicle model/year to what extent the data can be converted - we typically see 30-60% conversion in most cases. As such, we also offer that you can send us a raw log file that we can convert on your behalf to serve as a "demo" of what the DBC would yield in your use case before you purchase it. Of course, if you're the OEM of the vehicle in question, you'll most often have access to the full DBC file covering 100% of the data.

Below is a sample of DBC converted J1939 truck data:

#6 Visualize your data

A final step may be to visualize your data in mining dashboards.

You can see our dashboard intro on how to set up free, customizable Grafana dashboards. You can also set up your own BI integrations using the API or e.g. use other dashboard tools like Dash by Plotly - you decide.

Ready to start your mining telematics pilot?

Get your CANedge today!